Document Type : ORIGINAL RESEARCH ARTICLE

Author

Department of Civil Engineering, Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala Engineering College, Avadi, Chennai 600062, Tamil Nadu, India

Abstract

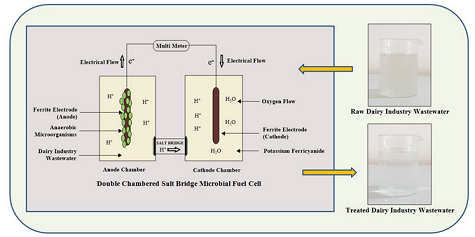

Taguchi L9 orthogonal array was implemented to select optimum values of process parameters and to attain the maximum removal of pollutants and power generation from dairy industry wastewater using double chambered salt bridge microbial fuel cell. The maximum chemical oxygen demand reduction, current, voltage, power, current density and power density in double chambered salt bridge microbial fuel cell from dairy industry wastewater was found to be 86.30 %, 16.10 mA, 886.34 mV, 14.27 mW, 1219.69 mA/m2 and 1081.06 mW/m2 respectively for the optimum value of 1M NaCl concentration, 10 % agar concentration and 0.10 m salt bridge length. Double chambered salt bridge microbial fuel cell was not only removed chemical oxygen demand and produced power, but it also removed other pollutants at the maximum level against the best optimum value of process parameters from the dairy industry wastewater. The proposed regression model was used to select the right combination of process parameters for obtaining a maximum reduction of pollutants and simultaneous power production from the dairy industry wastewater.

Graphical Abstract

Highlights

- Ferrite electrode used in anode and cathode chambers enhances DCSB-MFC performances towards bioelectricity production;

- The maximum COD reduction and power production in DCSB-MFC from dairy industry wastewater were found to be 86.30 % and 14.27 mW, respectively;

- Improvement in power production and pollutant reduction was observed with 1M NaCl concentration, 10% agar concentration and 0.05 m salt bridge length through the Taguchi optimization approach;

- A model simulation was framed to select the best combination of process parameters towards the targeted maximum power production and pollutants reduction from dairy industry wastewater using DCSB-MFC.

Keywords

Letters to Editor

[1] Letters that include statements of statistics, facts, research, or theories should include appropriate references, although more than three are discouraged.

[2] Letters that are personal attacks on an author rather than thoughtful criticism of the author’s ideas will not be considered for publication.

[3] Letters can be no more than 300 words in length.

[4] Letter writers should include a statement at the beginning of the letter stating that it is being submitted either for publication or not.

[5] Anonymous letters will not be considered.

[6] Letter writers must include their city and state of residence or work.

[7] Letters will be edited for clarity and length.

Send comment about this article