Document Type : ORIGINAL RESEARCH ARTICLE

Author

1 Department for Management of Science and Technology Development, Ton Duc Thang University, Ho Chi Minh City, Vietnam

2 Faculty of Environment and Labour Safety, Ton Duc Thang University, Ho Chi Minh City, Vietnam

Abstract

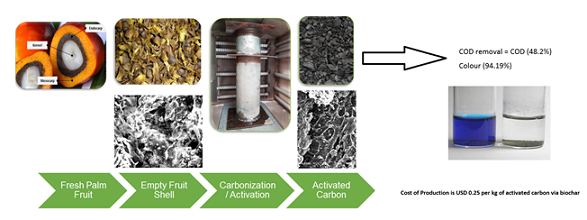

Conventional steam activation pyrolysis of waste materials such as oil palm kernel shell for production of biochar was investigated using central composite design. Conventional steam activation was carried out via an initial carbonization of oil palm kernel shell to obtain biochar and thereafter steam activation of the biochar using the conventional heating to produce activated carbon. Additionally, removal of chemical oxygen demand and colour was studied alongside the production. Optimum yield was obtained at about 90 min and 725oC. Out of the time duration, 80 min was for carbonation and 10 min was for steam activation. Further extension of time was not significant whereas increasing temperature was able to increase the pores found on the biochar. Under the optimum condition, fixed carbon was 19.39%, chemical oxygen demand and colour removal were 32.02 and 61.15%, respectively at 90 min adsorption time. However, when time was extended to 120 min, chemical oxygen demand (48.2%) and colour (94.19%) removal were achieved. The Brunauer–Emmett–Teller surface area and micropore area of the oil palm kernel shell based activated carbon was 620.45 m2/g and 550.4 m2/g, respectively. The conventional steam activation is an effective method that can be employed in production of activated carbon from waste oil palm kernel shell.

Graphical Abstract

Highlights

- Microporous activated carbon was produced via conventional steam activation;

- Conventional steam activation has shown an optimized limited time and temperature in activated carbon production;

- Optimal yield and adsorption was at 725oC and 90 minutes;

- The economic feasibility at USD 0.25/kg operational production cost is attractive.

Keywords

Letters to Editor

[1] Letters that include statements of statistics, facts, research, or theories should include appropriate references, although more than three are discouraged.

[2] Letters that are personal attacks on an author rather than thoughtful criticism of the author’s ideas will not be considered for publication.

[3] Letters can be no more than 300 words in length.

[4] Letter writers should include a statement at the beginning of the letter stating that it is being submitted either for publication or not.

[5] Anonymous letters will not be considered.

[6] Letter writers must include their city and state of residence or work.

[7] Letters will be edited for clarity and length.

Send comment about this article